- introduction

- Features

- advantages

- Application scenarios

- Inquiry now

- Related products

According to the notice released by the Department of Industry and Information Technology of Shandong Province on November 24, 2023, announcing the list of the first (set) technology equipment and key core component production enterprises and products in Shandong Province for 2023, the "FBE coated steel pipes production line" developed and promoted by Qingdao Huashi has won this honor

1. Breakthroughs have been achieved in the following core technologies

Internal and external epoxy synchronous coating, small volume high load-bearing conveyor wheel, high-speed internal shot blasting rust removal for small pipes, specialized conveying equipment and spraying process for ultra large pipes, digital coating control.

2. The overall performance of the product has reached the leading level in China. Compared with similar machines, advanced internal and external synchronization technology and small volume high load-bearing structure are used to achieve a perfect balance of processing specification range, processing speed, spraying effect, and equipment layout.

Compared with the existing two-step production line, it can significantly reduce energy consumption, shorten spraying time by nearly 50%, and increase the load-bearing capacity of a single conveyor wheel by three times.

4. It is suitable for rapid anti-corrosion processing of ultra large steel pipes with a length of 3200mm, 12 meters, and a weight of 30 tons, while saving equipment space.

5. Provided a highly intelligent overall solution for the rapid and precise spraying of ultra large steel pipes, elevating China's epoxy resin spraying anti-corrosion technology to a new level and playing a leading and exemplary role in the industry.

01

The electrostatic spraying system configured on the internal powder coating production line avoids pinholes in the internal coating caused by gun discharge.

02

The dust removal system configured on the production line can control powder overflow and is environmentally friendly and clean.

03

The powder closed circulation system configured on the external spraying line meets the full recycling and utilization of powder and the cleanliness of the production environment, reducing the labor intensity of workers.

04

The air volume adjustment of the powder dust removal system is reasonable, the filter cartridge dust collector has a novel design, high dust removal efficiency, clean and environmentally friendly, and the overall use of noise reduction treatment results in low noise.![]()

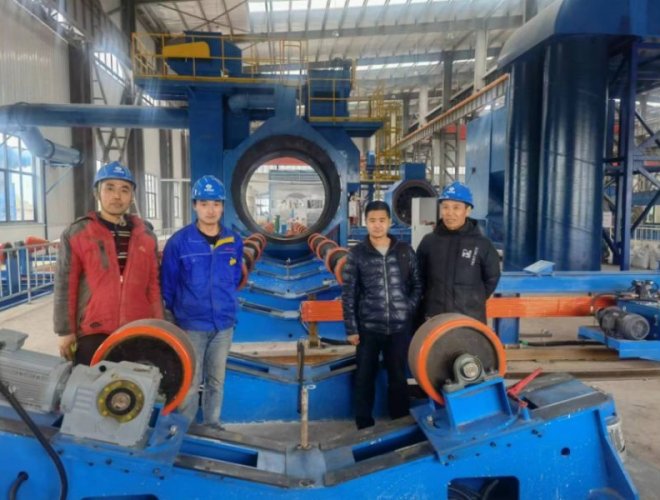

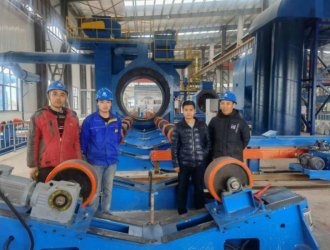

Technology convinces customers and quality impresses them, thus the brand influence of Qingdao Huashida continues to rise, attracting continuous customers to cooperate with Huashida. When customers purchase products from Huashida, price becomes the second consideration factor in their cooperation with Huashida. When Hefei Huarui Pipeline Company was purchasing a FBE coated steel pipes production line, Mr. Zhang of Huarui said, 'We choose Huashida's equipment, and the price is determined by you.'. This sentence is the best affirmation and appreciation of Huashida.