-

3PE Anti-corrosion coating Line

- - Steel pipe inner wall sand blasting rust removal production line

- - Multi-position steel pipe external epoxy (external plastic coating) anti-corrosion coating line

- - Round-extrusion 3LPE coating line

- - Steel pipe inside and outside epoxy powder coating anti-corrosion production line (inside and outside coating plastic, FBE) anti-corrosion production line

- - Steel pipe internal and external liquid coating spraying anti-corrosion production line.

- - Steel pipeline joints internal coating Robot

- - Steel Pipe Outer Wall Shot Blasting line

- - Steel pipe internal shot blasting line

- - Steel pipe 3LPE anti-corrosion coating production line

- - Steel elbow 3PE anti-corrosion production line

-

Pre-Insulated Pipe Production Line

-

Rubber Foam Insulation tube/sheet Production Line

-

PE PP Sheet/film/Board Extrusion Line

- - Water-proof Coiled Material /GEO-membrane Film Extrusion Line

- - PE/PP/PS/HIPS/ABS Single extrusion & Multi-layer Sheet Co-Extrusion Line

- - Adhesive coating line of heat shrinkable sleeve

- - Fibre reinforced 3-layer PE cross-linked heat shrinkable sleeve backing film production line

- - PE Carbon Fibre Spiral Pipe Extrusion Line

- - PE PP Sheet/Board Extrusion Line

- - Electro-fusion girth welding joint closure production line

- - Heat Shrinkable Sleeve extrusion and Coating Line

-

Pipe Fittings

-

HDPE pipe production line

-

HDPE/PP Double Wall Corrugated Pipe Production Line

-

HDPE Hollow Wall Corrugated Pipe/ Structured Wall Pipe Extrusion Line

The high-speed Shots (steel shots, steel sand, etc.) are casted to the outer surface of the steel pipe by shot blasters. The Shots hit the surface of the steel pipe with a strong impact force to make the rust, scale and other impurities fall off to achieve the purpose of rust removal.

- introduction

- Features

- Technical parameters

- advantages

- Application scenarios

- Inquiry now

- Related products

This method has high rust removal efficiency and can quickly remove the stubborn rust layer on the surface of the steel pipe, and at the same time of rust removal, the impact of the shots can also produce a certain crushing stress on the surface of the steel pipe, improve the power of resist fatigue strength and corrosion resistance of the steel pipe.

Technical process

The steel pipes that have passed the appearance inspection enter the external shot blasting line. On the conveyor the steel pipes connected end to end, rotating and going spirally forward, and enter the external shot blasting room for rust removal operations.

The steel pipes connected end to end on the conveyor and pass through the shot blasting machine. The shot blaster drives the steel grits to hit the outer surface of the steel pipe, so that the oxide scale on the outside of the steel pipe is knocked off by the steel grits, and a clean outer surface is obtained to achieve the Sa2.5 level of cleanliness specified in the coating standard.

During the shot blasting process, a certain amount of steel wire segments are added to the grits, and the required anchor pattern depth is formed under the impact of the steel wire segments to enhance the adhesion of the coating.

Video:

Rust removal equipment

Steel pipe transmission equipment

The production line includes the following equipment

No. | Equipment | Quantity

|

1 | Steel pipe rack

| 1 set |

2 | Steel pipe on-line ferry mechanism | 2 sets

|

3 | Hydraulic station 1 for 2

| 2 sets

|

4 | Conveyor system

| 1 set

|

5 | Shot blasting machine

| 1 unit

|

6 | Cyclone dust collector

| 1 unit

|

7 | Pulse filter cartridge dust collector

| 1 unit

|

8 | Centrifugal induced draft fans | 1 unit |

9 | Electrical control system

| 1 set

|

10 | Steel pipe offline rack | 1 set

|

1 1 | Steel pipe offline ferry mechanism | 2 sets |

Production line parameters:

(1)Steel pipe diameter range:60mm-4200mm

(2)Processing capacity:≥400㎡/h

(3)Cleaning level:Sa2.5 class

(4)Used material: Steel sand, steel shot, steel wire segment, etc

(5)Main equipment: Cleaning room, Shot blaster , conveyor, pipe uploading mechanism, pipe downloading mechanism, spiral conveyor, elevator, maintenance platform, separator, dust removal system and electric control system.

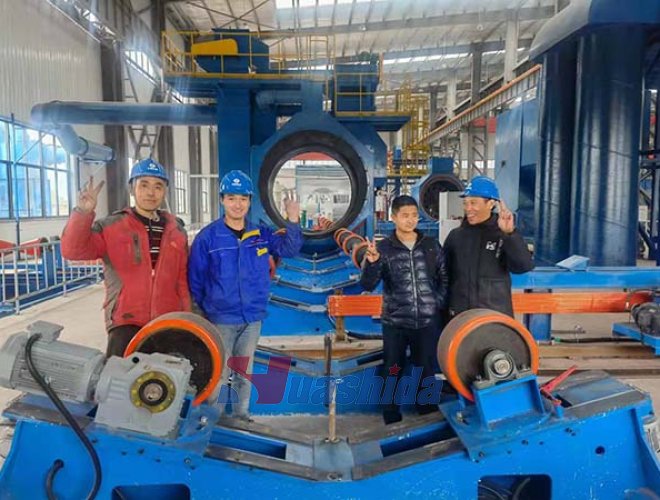

Production site

|  |

Overseas shipment

|  |

|  |

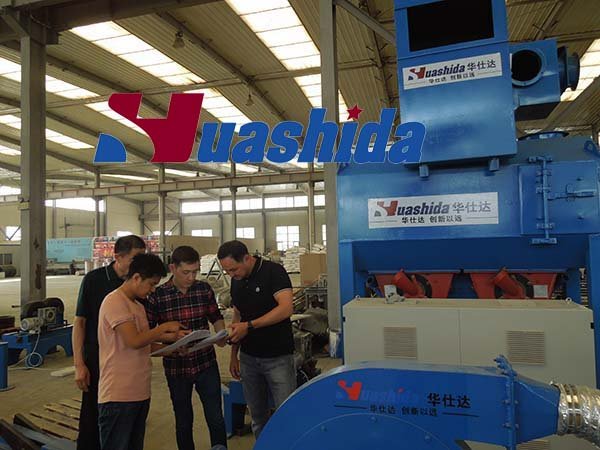

Customer visit

|  |

|  |

Overseas exhibition

|  |