-

3PE Anti-corrosion coating Line

- - Steel pipe inner wall sand blasting rust removal production line

- - Multi-position steel pipe external epoxy (external plastic coating) anti-corrosion coating line

- - Round-extrusion 3LPE coating line

- - Steel pipe inside and outside epoxy powder coating anti-corrosion production line (inside and outside coating plastic, FBE) anti-corrosion production line

- - Steel pipe internal and external liquid coating spraying anti-corrosion production line.

- - Steel pipeline joints internal coating Robot

- - Steel Pipe Outer Wall Shot Blasting line

- - Steel pipe internal shot blasting line

- - Steel pipe 3LPE anti-corrosion coating production line

- - Steel elbow 3PE anti-corrosion production line

-

Pre-Insulated Pipe Production Line

-

Rubber Foam Insulation tube/sheet Production Line

-

PE PP Sheet/film/Board Extrusion Line

- - Water-proof Coiled Material /GEO-membrane Film Extrusion Line

- - PE/PP/PS/HIPS/ABS Single extrusion & Multi-layer Sheet Co-Extrusion Line

- - Adhesive coating line of heat shrinkable sleeve

- - Fibre reinforced 3-layer PE cross-linked heat shrinkable sleeve backing film production line

- - PE Carbon Fibre Spiral Pipe Extrusion Line

- - PE PP Sheet/Board Extrusion Line

- - Electro-fusion girth welding joint closure production line

- - Heat Shrinkable Sleeve extrusion and Coating Line

-

Pipe Fittings

-

HDPE pipe production line

-

HDPE/PP Double Wall Corrugated Pipe Production Line

-

HDPE Hollow Wall Corrugated Pipe/ Structured Wall Pipe Extrusion Line

This kind of rubber insulation pipe equipment is developed by advanced technology, rubber foam pipe, commonly known as sponge pipe, rubber and plastic insulation pipe equipment is mainly composed of extruder, die mold, infrared radiation heating furnace, foam heating furnace, traction and automatic cutting equipment, its products are widely used in air conditioning insulation pipe, edge tube plate, high-grade handle, fitness equipment sheath and other fields.

- introduction

- Features

- Technical parameters

- advantages

- Application scenarios

- Inquiry now

- Related products

Rubber Foam Insulation tube/sheet Production Line is used for extrusion of various foamed or non foamed rubber pipes, boards, handles, sheaths, sealing strips, etc. The raw materials used are high-performance nitrile rubber, polyvinyl chloride (NBR, PVC), and various other high-quality materials, which are foamed through special processes to produce soft insulation and energy-saving materials.

Focus on rubber and plastic foam insulation pipe/insulation board equipment research and development and

production, to provide customers with high-quality and stable production equipment.

Provide turnkey engineering services for production process, production formula, plant design, technical personnel

training.

1. Good level of automation

This production line has the advantages of fast extrusion speed, high degree of automation, excellent safety performance, advanced technology in design, structural performance, vulcanization quality, and other aspects.

2. Superior product performance in production

The rubber sponge insulation material produced is a closed cell elastic material, which has excellent properties such as softness, bending resistance, cold resistance, heat resistance, flame retardancy, waterproofing, low thermal conductivity, shock absorption, sound absorption, etc. Therefore, it is a high-quality new generation of insulation material.

3. Wide range of product applications

4.The product has a wide range of applications, such as various cold and hot medium pipelines and containers in industries and departments such as central air conditioning, construction, chemical, pharmaceutical, textile, metallurgy, ships, vehicles, electrical appliances, etc., which can achieve the effect of reducing cold and heat losses.

5.This product has excellent properties such as softness, bending resistance, cold resistance, heat resistance, flame retardancy, waterproofing, low thermal conductivity, shock absorption, and sound absorption.

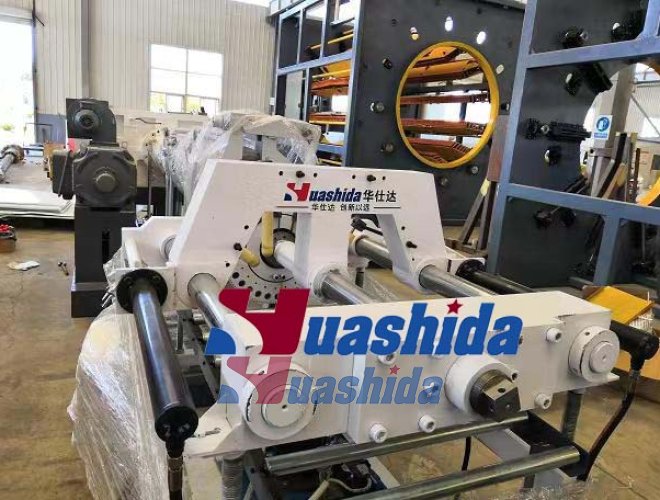

Core components

Production site

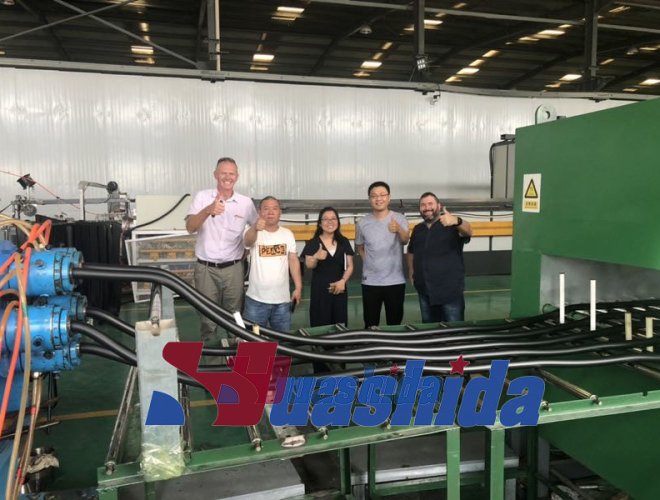

Customer case

Model | Floor space | Line Length | Output capability | Total power |

120 | 1800 | 80m | 150-180 | 500kw |

150 | 2400 | 100m | 200-240 | 650kw |

01 High extrusion yield and good quality

02 Automatic temperature control

03 Low energy consumption

04 High production efficiency

05 High market share

In the spacious and bright production workshop of Rongjia in Weifang, two Rubber Foam Insulation tube/sheet Production Line of 120 and 150 types are running at high speed. The workers are busy in an orderly manner, and the operators are continuously feeding according to the formula and dosage. After being processed by an internal mixer, the substrate is made and then processed by an oven and a mixer. After cutting and testing, the qualified pipes are packaged and shipped. The entire production line has only three or four employees working, with high production efficiency and good product quality. The production line manager highly praised the quality and production speed of Huashida machines.