-

3PE Anti-corrosion coating Line

- - Steel pipe inner wall sand blasting rust removal production line

- - Multi-position steel pipe external epoxy (external plastic coating) anti-corrosion coating line

- - Round-extrusion 3LPE coating line

- - Steel pipe inside and outside epoxy powder coating anti-corrosion production line (inside and outside coating plastic, FBE) anti-corrosion production line

- - Steel pipe internal and external liquid coating spraying anti-corrosion production line.

- - Steel pipeline joints internal coating Robot

- - Steel Pipe Outer Wall Shot Blasting line

- - Steel pipe internal shot blasting line

- - Steel pipe 3LPE anti-corrosion coating production line

- - Steel elbow 3PE anti-corrosion production line

-

Pre-Insulated Pipe Production Line

-

Rubber Foam Insulation tube/sheet Production Line

-

PE PP Sheet/film/Board Extrusion Line

- - Water-proof Coiled Material /GEO-membrane Film Extrusion Line

- - PE/PP/PS/HIPS/ABS Single extrusion & Multi-layer Sheet Co-Extrusion Line

- - Adhesive coating line of heat shrinkable sleeve

- - Fibre reinforced 3-layer PE cross-linked heat shrinkable sleeve backing film production line

- - PE Carbon Fibre Spiral Pipe Extrusion Line

- - PE PP Sheet/Board Extrusion Line

- - Electro-fusion girth welding joint closure production line

- - Heat Shrinkable Sleeve extrusion and Coating Line

-

Pipe Fittings

-

HDPE pipe production line

-

HDPE/PP Double Wall Corrugated Pipe Production Line

-

HDPE Hollow Wall Corrugated Pipe/ Structured Wall Pipe Extrusion Line

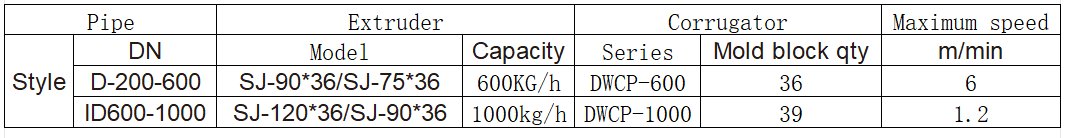

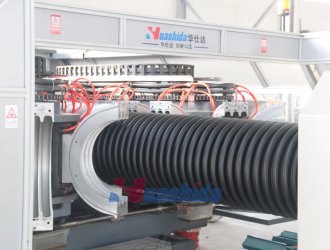

Double Wall Corrugated Pipe Production Line is a new type of high-speed water-cooled corrugated pipe production line developed and designed by ourselves based on advanced foreign technology. Mainly using polypropylene (PP) or high-density polyethylene (HDPE) as raw materials. Production of single and double wall corrugated pipes. Due to its unique structure, this pipe has the advantages of light weight, good impact resistance, strong corrosion resistance, and cold and heat resistance. It is widely used in urban drainage (water supply), geographical infiltration, construction water supply and drainage, PEF, wire and cable laying, bridge steel cable sheath, agricultural irrigation, and other fields.

- introduction

- Features

- Technical parameters

- Inquiry now

- Related products

The DWCP series high-speed corrugated pipe forming machine adopts a closed water-cooled structure, and the mold

base drives the left and right modules to move within the closed curve. The mold base adopts a gear dynamic structure, which has the advantages of automatic compensation for mechanical wear, smooth operation, low noise, long service life, and highsynchronization. The unique design of the circulating water circuit has high reliability, good cooling effect, and low water impact in the pipeline, which improves the reliability of continuous production of pipes and ensures the surface forming quality of pipes.