-

3PE Anti-corrosion coating Line

- - Steel pipe inner wall sand blasting rust removal production line

- - Multi-position steel pipe external epoxy (external plastic coating) anti-corrosion coating line

- - Round-extrusion 3LPE coating line

- - Steel pipe inside and outside epoxy powder coating anti-corrosion production line (inside and outside coating plastic, FBE) anti-corrosion production line

- - Steel pipe internal and external liquid coating spraying anti-corrosion production line.

- - Steel pipeline joints internal coating Robot

- - Steel Pipe Outer Wall Shot Blasting line

- - Steel pipe internal shot blasting line

- - Steel pipe 3LPE anti-corrosion coating production line

- - Steel elbow 3PE anti-corrosion production line

-

Pre-Insulated Pipe Production Line

-

Rubber Foam Insulation tube/sheet Production Line

-

PE PP Sheet/film/Board Extrusion Line

- - Water-proof Coiled Material /GEO-membrane Film Extrusion Line

- - PE/PP/PS/HIPS/ABS Single extrusion & Multi-layer Sheet Co-Extrusion Line

- - Adhesive coating line of heat shrinkable sleeve

- - Fibre reinforced 3-layer PE cross-linked heat shrinkable sleeve backing film production line

- - PE Carbon Fibre Spiral Pipe Extrusion Line

- - PE PP Sheet/Board Extrusion Line

- - Electro-fusion girth welding joint closure production line

- - Heat Shrinkable Sleeve extrusion and Coating Line

-

Pipe Fittings

-

HDPE pipe production line

-

HDPE/PP Double Wall Corrugated Pipe Production Line

-

HDPE Hollow Wall Corrugated Pipe/ Structured Wall Pipe Extrusion Line

Polyurethane spraying Polyethylene winding pre insulation pipe production line,developed independently by HUASHIDA company, owns a number of national patents. According to the third-party standardization evaluation, the technical advancement level is level 5, reaching the domestic advanced level.

- introduction

- Features

- Technical parameters

- advantages

- Application scenarios

- Inquiry now

- Related products

It won the title of the first set of technical equipment in Shandong Province. The unit adopts continuous spraying or intermittent spraying production process. High degree of automation, fast production efficiency, saving raw materials, foaming closed cell rate increased, water absorption reduced, trinity molding, more reliable performance. Low carbon environmental protection and higher economic and social benefits.

Our company independently develops Polyurethane Spraying Foam Preinsulated Steel Pipe Making Machine, which consists of three parts: Steel Pipe Shot Blasting Machine, polyurethane spray production line, and PE winding production line.

Production steps:

Step 1: Rust removal on the outer wall of the steel pipe

Step 2: After rust removal, the steel pipe is lifted to the pipeline rack - it is transported to the spraying conveyor line by a pipe transport cart - the steel pipe is heated - polyurethane spraying - it is transported to the storage platform by a lifting cart - PE layer winding - water spray cooling - connection incision - finished pipe offline - finished pipe inspection - port repair - spray code packaging offline

|  |  |

| Steel Pipe Shot Blasting Machine | polyurethane spray production line | PE winding production line. |

1. Dust removal meets environmental standards

By adopting an intelligent shot blasting and rust removal scheme, the equipment can be opened sequentially and self locked, the shot blasting motor can save energy through frequency conversion, the sand volume can be set according to the pipe diameter, the air washing system can clean the shot sand, and the plug type can quickly change specifications. The three-level dust removal meets environmental protection standards.

2. Suitable for the production of large-diameter insulation pipes

By adopting a high load-bearing spiral conveyor line, the polyurethane foam spraying and polyethylene winding processes are continuously carried out, which has the advantages of high efficiency, energy saving, speed, and stability. It is suitable for the continuous production of large-diameter insulation pipes and saves investment in transportation equipment.

3. Automated operation of production lines

Realize automatic processing of upper and lower pipes. The conveyor line is equipped with upper pipe sensors, automatic acceleration tracking sensors, automatic acceleration detachment sensors, detachment confirmation sensors, and automatic descent sensors to ensure the automated operation of the production line.

4. Spraying saves materials

The online spraying speed of pipelines is fast; Constant intermediate frequency power, infrequent on/off, minimal impact on the power grid, balanced temperature, and energy conservation; Continuous spraying saves raw materials, and the head and tail of the steel pipe are automatically connected to ensure consistent surface thickness during spraying.

5. Efficient extrusion of pipelines

Using efficient and energy-saving extruders for extrusion, and using mechanical clamping devices for winding and compacting; Automatic cutting, triple cutting of anti-corrosion coating, automatic pipe removal during offline production, accelerating detachment.

6. Automated precision machining of pipeline interfaces

Centralize multiple processing steps on a single device for automated processing, achieving precise control over the size, angle, and blunt edge dimensions of the pipe opening.

Wrapped finished pipe

Rust Removal Chuck trolley

Spray winding insulation pipe Spray winding transmission equipment

Spray winding Production workshop pictures

| Steel pipe diameter | Thickness of insulation pipe | Diameter of outer protective tube | Minimum wall thickness of outer protective layer |

| 500 | 30-60 | 580-640 | 5.6 |

| 630 | 30-60 | 710-772 | 6.6 |

| 710 | 30-60 | 790-850 | 7.2 |

| 800 | 30-60 | 885-950 | 7.9 |

| 900 | 30-60 | 980-1054 | 8.7 |

| 1000 | 30-60 | 1090-1155 | 9.4 |

| 1100 | 30-60 | 1190-1250 | 10.2 |

| 1200 | 40-100 | 1316-1436 | 11 |

| 1400 | 50-100 | 1538-1638 | 12.5 |

| 1500 | 50-100 | 1638-1738 | 12.5 |

Production line parameter:

(1) Steel pipe range: 206mm-1820mm

(2) Processing capacity:≤250㎡/h

(3) Cleaning class: Sa2.5

(4) Used material: ISO (isocyanate), POLY (premixed polyether polyols), PE

(5) Main equipment: Shot blasting and rust removal production line, Polyurethane spray production line, PE winding production line.

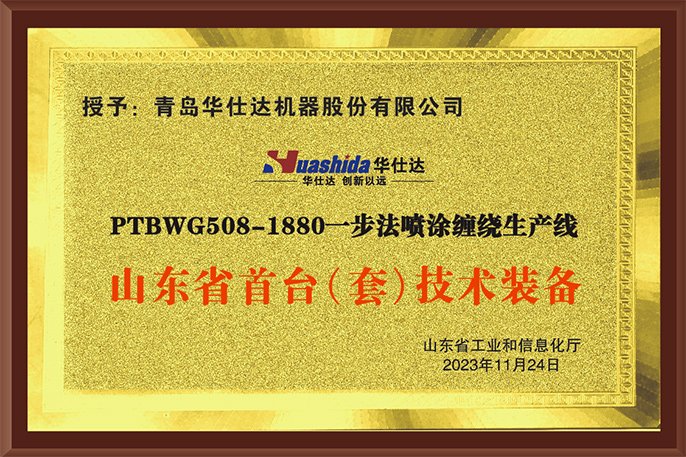

01 Awarded the first (set) technical equipment in Shandong Province

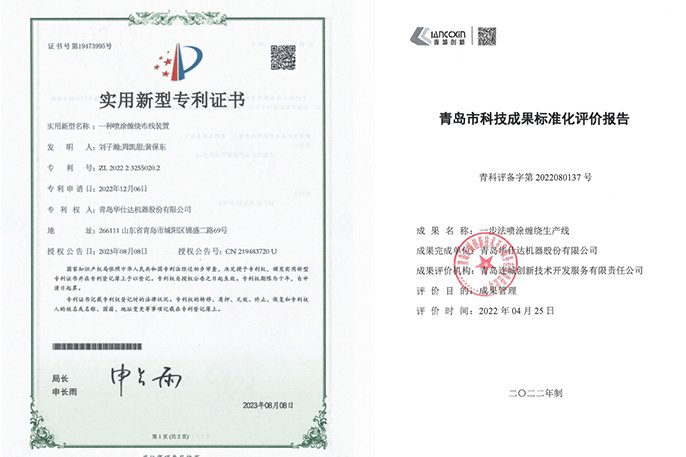

02 Evaluation Report on Standardization of Scientific and Technological Achievements in Qingdao City

03 Having multiple national patents

04 Intelligence, automation, and reducing manual labor

05 Efficient and energy-saving, with low production costs

06 Stable and reliable, with a high yield of finished products and minimal waste

|  |

Qingdao Huashida has exported a spray winding production line to Jeddah Company in Saudi Arabia, and it has been installed and operated. The cooperation between Huashida and Jeddah not only marks another breakthrough for Chinese pipeline equipment in the international market, but also demonstrates the competitiveness of Qingdao Huashida in the field of equipment manufacturing.