-

3PE Anti-corrosion coating Line

- - Steel pipe inner wall sand blasting rust removal production line

- - Multi-position steel pipe external epoxy (external plastic coating) anti-corrosion coating line

- - Round-extrusion 3LPE coating line

- - Steel pipe inside and outside epoxy powder coating anti-corrosion production line (inside and outside coating plastic, FBE) anti-corrosion production line

- - Steel pipe internal and external liquid coating spraying anti-corrosion production line.

- - Steel pipeline joints internal coating Robot

- - Steel Pipe Outer Wall Shot Blasting line

- - Steel pipe internal shot blasting line

- - Steel pipe 3LPE anti-corrosion coating production line

- - Steel elbow 3PE anti-corrosion production line

-

Pre-Insulated Pipe Production Line

-

Rubber Foam Insulation tube/sheet Production Line

-

PE PP Sheet/film/Board Extrusion Line

- - Water-proof Coiled Material /GEO-membrane Film Extrusion Line

- - PE/PP/PS/HIPS/ABS Single extrusion & Multi-layer Sheet Co-Extrusion Line

- - Adhesive coating line of heat shrinkable sleeve

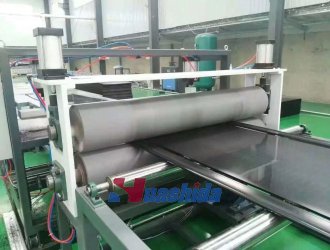

- - Fibre reinforced 3-layer PE cross-linked heat shrinkable sleeve backing film production line

- - PE Carbon Fibre Spiral Pipe Extrusion Line

- - PE PP Sheet/Board Extrusion Line

- - Electro-fusion girth welding joint closure production line

- - Heat Shrinkable Sleeve extrusion and Coating Line

-

Pipe Fittings

-

HDPE pipe production line

-

HDPE/PP Double Wall Corrugated Pipe Production Line

-

HDPE Hollow Wall Corrugated Pipe/ Structured Wall Pipe Extrusion Line

This line major used on electro-fusion girth welding joint closuremanufacture of HDPE structured wall spiral pipe andpre-insulated pipe(PU foam pipe with HDPE outside casing).

- introduction

- Features

- Technical parameters

- advantages

- Application scenarios

- Inquiry now

- Related products

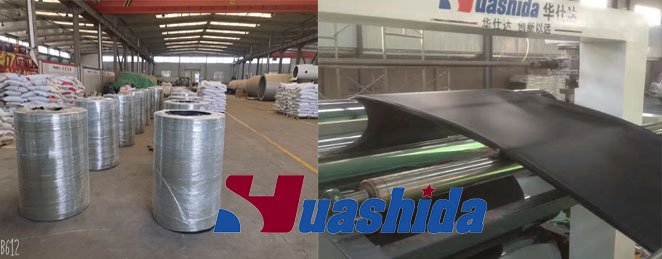

The Qingdao Huashida Pipe Electrofusion Sleeve production line includes sheet production lines, covering machines, edging machines, bending machines and other forming equipment, as well as construction site specific electric Electrofusion welding machines.

1. High degree of automation

Intelligent control ensures linkage, unified adjustment, and synchronized operation.

2. Low consumption and energy-saving

Quality assurance, long service life, low energy consumption.

3. Customized production

Customers proactively choose, meet different customer requirements, and provide lifelong technical support and repair services.

4. After sales service

The debugging personnel did not waste a penny on the buyer and completed the debugging with minimal manpower and material resources. They arrived at the site within 48 hours with just one phone call.

5. Intelligent operation

PLC control, intelligent operation, low cost, power-saving, water-saving, labor-saving, high safety factor, protecting the personal safety of operators.

6. Product Services

Detailed PPT introduction and improvement of video image library, providing customers with comprehensive market analysis and cost analysis, and providing customized solutions.

Applicable materials | PP/PE/PS/HIPS/ABS/PVC |

Range | Single layer, double layer, multi-layer |

thickness | 0.1-30m |

width | 800mm-1600mm |

Possessing a team of high-end technical talents.

Higher speed, higher efficiency, more stable and reliable.

70% of products are shipped to Europe, America, the Middle East, Central Asia, Africa, Russia and other countries and regions.

High market share.

On March 21, the Qingdao Huashida 3PE anti-corrosion production line vehicle completed loading from the factory, and three trucks were dispatched one after another to Kazakhstan. This is another export of Qingdao Huashida to Kazakhstan. After receiving the order at the end of last year, the company immediately organized relevant departments to hold a project launch meeting, coordinate production organization, sort out the equipment spare parts list in detail, formulate specific production plans, and the procurement department coordinated the raw materials on site and cut the materials for production. During the production process, the project team held promotion meetings many times, strictly compared the process standards and requirements, and increased the inspection efforts. At the beginning of this year, Huashida was intensively preparing for production and manufacturing, completing the project before the specified construction period and delivering the goods on time.