-

3PE Anti-corrosion coating Line

- - Steel pipe inner wall sand blasting rust removal production line

- - Multi-position steel pipe external epoxy (external plastic coating) anti-corrosion coating line

- - Round-extrusion 3LPE coating line

- - Steel pipe inside and outside epoxy powder coating anti-corrosion production line (inside and outside coating plastic, FBE) anti-corrosion production line

- - Steel pipe internal and external liquid coating spraying anti-corrosion production line.

- - Steel pipeline joints internal coating Robot

- - Steel Pipe Outer Wall Shot Blasting line

- - Steel pipe internal shot blasting line

- - Steel pipe 3LPE anti-corrosion coating production line

- - Steel elbow 3PE anti-corrosion production line

-

Pre-Insulated Pipe Production Line

-

Rubber Foam Insulation tube/sheet Production Line

-

PE PP Sheet/film/Board Extrusion Line

- - Water-proof Coiled Material /GEO-membrane Film Extrusion Line

- - PE/PP/PS/HIPS/ABS Single extrusion & Multi-layer Sheet Co-Extrusion Line

- - Adhesive coating line of heat shrinkable sleeve

- - Fibre reinforced 3-layer PE cross-linked heat shrinkable sleeve backing film production line

- - PE Carbon Fibre Spiral Pipe Extrusion Line

- - PE PP Sheet/Board Extrusion Line

- - Electro-fusion girth welding joint closure production line

- - Heat Shrinkable Sleeve extrusion and Coating Line

-

Pipe Fittings

-

HDPE pipe production line

-

HDPE/PP Double Wall Corrugated Pipe Production Line

-

HDPE Hollow Wall Corrugated Pipe/ Structured Wall Pipe Extrusion Line

PERT Rigid Pre-insulated Pipe Production Line

The production line adopts international advanced technology, combining modern automation with efficient production processes, which can significantly improve production efficiency and reduce production costs. Has good sealing performance, no chemical corrosion or oxidation in the inner tube.

Inquiry Now

- introduction

- Technical parameters

- Application scenarios

- Inquiry now

- Related products

introduction

Widely used in fields such as building water supply and refrigeration systems.

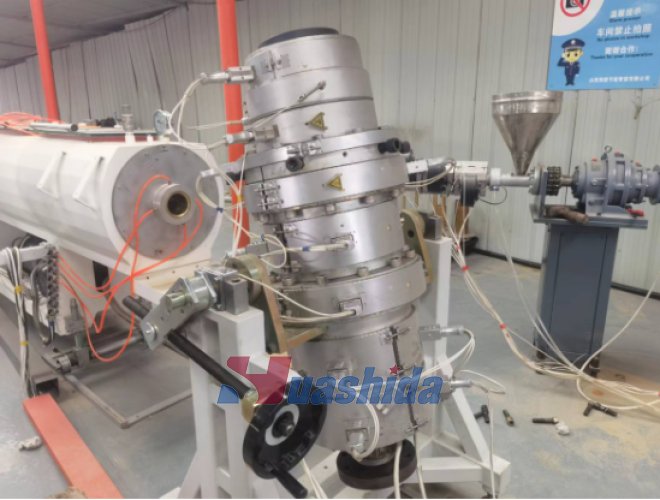

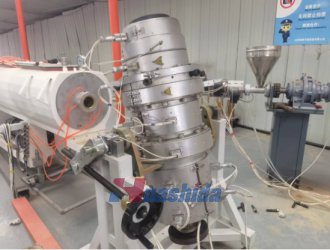

Equipment composition: feeding machine, extruder, vacuum sizing, cooling, traction, cutting, unloading and other integrated components.

Technical parameters

| Mode | Dia. Range | Extruder | Power | Capacity |

| PERT-110 | 20-110 | 60/33 | 150KW | 180KG |

| PERT-250 | 75-250 | 75/35 | 200KW | 250KG |

| PERT-350 | 160-350 | 90/33 | 260KW | 500KG |

Application scenarios

Construction case

Inquiry now