-

3PE Anti-corrosion coating Line

- - Steel pipe inner wall sand blasting rust removal production line

- - Multi-position steel pipe external epoxy (external plastic coating) anti-corrosion coating line

- - Round-extrusion 3LPE coating line

- - Steel pipe inside and outside epoxy powder coating anti-corrosion production line (inside and outside coating plastic, FBE) anti-corrosion production line

- - Steel pipe internal and external liquid coating spraying anti-corrosion production line.

- - Steel pipeline joints internal coating Robot

- - Steel Pipe Outer Wall Shot Blasting line

- - Steel pipe internal shot blasting line

- - Steel pipe 3LPE anti-corrosion coating production line

- - Steel elbow 3PE anti-corrosion production line

-

Pre-Insulated Pipe Production Line

-

Rubber Foam Insulation tube/sheet Production Line

-

PE PP Sheet/film/Board Extrusion Line

- - Water-proof Coiled Material /GEO-membrane Film Extrusion Line

- - PE/PP/PS/HIPS/ABS Single extrusion & Multi-layer Sheet Co-Extrusion Line

- - Adhesive coating line of heat shrinkable sleeve

- - Fibre reinforced 3-layer PE cross-linked heat shrinkable sleeve backing film production line

- - PE Carbon Fibre Spiral Pipe Extrusion Line

- - PE PP Sheet/Board Extrusion Line

- - Electro-fusion girth welding joint closure production line

- - Heat Shrinkable Sleeve extrusion and Coating Line

-

Pipe Fittings

-

HDPE pipe production line

-

HDPE/PP Double Wall Corrugated Pipe Production Line

-

HDPE Hollow Wall Corrugated Pipe/ Structured Wall Pipe Extrusion Line

- introduction

- Features

- Technical parameters

- advantages

- Application scenarios

- Inquiry now

- Related products

The Qingdao Huashida PE PP Sheet/Board Extrusion Line can achieve a width of 1600mm boards, and this Extrusion Lin can produce various PE raw materials, with a width range of 800-1600mm.

|  |  |

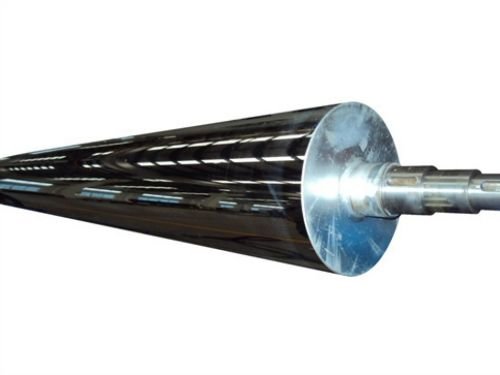

Extruder Adopting a PEPP high-efficiency extruder, the extrusion part adopts a forced water-cooled feeding section, the machine barrel is opened, and the power consumption of the main drive motor is significantly reduced; Strong adaptability to materials and excellent plasticization effect. | Die head The special design make thickness adjustment easy and accurate to operate. | Three roll calender According to the different widths, vertical and inclined structures and specially designed roller inner structures are adopted to ensure precise temperature control of the roller and ensure the surface brightness of the geotextile and waterproof membrane; The surface of the high-precision mirror roller is plated with hard chromium, which has high strength and long service life. |

|

| |

| Cooling Rack | Control system |

1. High degree of automation

Intelligent control ensures linkage, unified adjustment, and synchronized operation.

2. Low consumption and energy-saving

Quality assurance, long service life, low energy consumption.

3. Customized production

Customers proactively choose, meet different customer requirements, and provide lifelong technical support and repair services.

4. After sales service

The debugging personnel did not waste a penny on the buyer and completed the debugging with minimal manpower and material resources. They arrived at the site within 48 hours with just one phone call.

5. Intelligent operation

PLC control, intelligent operation, low cost, power-saving, water-saving, labor-saving, high safety factor, protecting the personal safety of operators.

6. Product Services

Detailed PPT introduction and improvement of video image library, providing customers with comprehensive market analysis and cost analysis, and providing customized solutions.

| Applicable materials | PP/PE/PS/HIPS/ABS/PVC |

| Range | Single layer, double layer, multi-layer |

| Thickness | 0.1-30mm |

| Width | 800mm-1600mm |

01 Originating from advanced technology in Germany

02 20 years of continuous technological innovation.

03 Provide complete production equipment for over 400 enterprises

04 Provide 24-hour response service to customers and solve their concerns and difficulties

05 70% customer repurchase rate, making Huashida a highly recognized brand by customers

06 The product is sold to countries and regions such as Europe, America, the Middle East, Central Asia, Africa, Russia, etc

Ola from Russia is an old friend of Huashida and has visited Huashida several times. This time, she accompanied Moscow customers to visit Huashida's board production line. The PE/PP Sheet produced by Huashida's PE PP Sheet/Board Extrusion Line are diverse in materials and widely used, which can generate more value-added benefits for customers. Russian customers have signed purchase contracts with Huashida, and the equipment is currently operating smoothly in production.