-

3PE Anti-corrosion coating Line

- - Steel pipe inner wall sand blasting rust removal production line

- - Multi-position steel pipe external epoxy (external plastic coating) anti-corrosion coating line

- - Round-extrusion 3LPE coating line

- - Steel pipe inside and outside epoxy powder coating anti-corrosion production line (inside and outside coating plastic, FBE) anti-corrosion production line

- - Steel pipe internal and external liquid coating spraying anti-corrosion production line.

- - Steel pipeline joints internal coating Robot

- - Steel Pipe Outer Wall Shot Blasting line

- - Steel pipe internal shot blasting line

- - Steel pipe 3LPE anti-corrosion coating production line

- - Steel elbow 3PE anti-corrosion production line

-

Pre-Insulated Pipe Production Line

-

Rubber Foam Insulation tube/sheet Production Line

-

PE PP Sheet/film/Board Extrusion Line

- - Water-proof Coiled Material /GEO-membrane Film Extrusion Line

- - PE/PP/PS/HIPS/ABS Single extrusion & Multi-layer Sheet Co-Extrusion Line

- - Adhesive coating line of heat shrinkable sleeve

- - Fibre reinforced 3-layer PE cross-linked heat shrinkable sleeve backing film production line

- - PE Carbon Fibre Spiral Pipe Extrusion Line

- - PE PP Sheet/Board Extrusion Line

- - Electro-fusion girth welding joint closure production line

- - Heat Shrinkable Sleeve extrusion and Coating Line

-

Pipe Fittings

-

HDPE pipe production line

-

HDPE/PP Double Wall Corrugated Pipe Production Line

-

HDPE Hollow Wall Corrugated Pipe/ Structured Wall Pipe Extrusion Line

The main feature of this equipment is that multiple processes of making insulation pipes, such as extruding outer protective pipes and pouring insulation materials, are completed continuously on the same production line, with high production efficiency.

- introduction

- Technical parameters

- advantages

- Inquiry now

- Related products

It is mainly used to manufacture polyurethane insulation pipes, etc., which can make the inner pipe, insulation layer and outer sheath of the insulation pipe tightly combined. Its degree of automation can effectively reduce manual operation links and improve the stability of product quality. It is widely used in the construction of pipelines that require insulation, such as heating pipelines and oil pipelines.

Production line parameters:

(1) Steel pipe coverage: 40mm-406mm

(2) Processing capacity: ≤250㎡/h

(3) Cleaning level: Sa2.5

(4) Materials used: black material (isocyanate), white material (combined polyether)

(5) Main equipment: steel pipe external rust removal equipment, PE extrusion equipment, molding molds, deviation correction equipment, cooling equipment, cutting equipment, transmission equipment, spray marking equipment, etc.

PPR insulation finished pipe Finished insulation pipe delivery

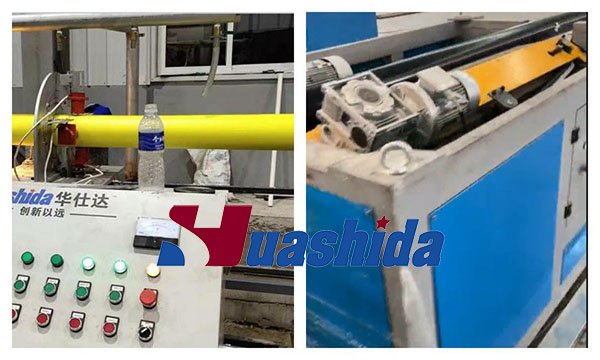

Operation table Positioning equipment

Positioning equipment Extruder head mold

Web correcting machine Double blade cutting equipment

Polyurethane insulation pipe finished product