-

3PE Anti-corrosion coating Line

- - Steel pipe inner wall sand blasting rust removal production line

- - Multi-position steel pipe external epoxy (external plastic coating) anti-corrosion coating line

- - Round-extrusion 3LPE coating line

- - Steel pipe inside and outside epoxy powder coating anti-corrosion production line (inside and outside coating plastic, FBE) anti-corrosion production line

- - Steel pipe internal and external liquid coating spraying anti-corrosion production line.

- - Steel pipeline joints internal coating Robot

- - Steel Pipe Outer Wall Shot Blasting line

- - Steel pipe internal shot blasting line

- - Steel pipe 3LPE anti-corrosion coating production line

- - Steel elbow 3PE anti-corrosion production line

-

Pre-Insulated Pipe Production Line

-

Rubber Foam Insulation tube/sheet Production Line

-

PE PP Sheet/film/Board Extrusion Line

- - Water-proof Coiled Material /GEO-membrane Film Extrusion Line

- - PE/PP/PS/HIPS/ABS Single extrusion & Multi-layer Sheet Co-Extrusion Line

- - Adhesive coating line of heat shrinkable sleeve

- - Fibre reinforced 3-layer PE cross-linked heat shrinkable sleeve backing film production line

- - PE Carbon Fibre Spiral Pipe Extrusion Line

- - PE PP Sheet/Board Extrusion Line

- - Electro-fusion girth welding joint closure production line

- - Heat Shrinkable Sleeve extrusion and Coating Line

-

Pipe Fittings

-

HDPE pipe production line

-

HDPE/PP Double Wall Corrugated Pipe Production Line

-

HDPE Hollow Wall Corrugated Pipe/ Structured Wall Pipe Extrusion Line

PERT/PEX flexible polyurethane pre-insulated pipe production line

The flexible polyurethane pre-insulated pipe production line is an advanced equipment for producing polymer pressure inner pipes (PERT, PEX) and insulating the inner pipes with polyurethane foam.

- introduction

- Features

- Technical parameters

- advantages

- Application scenarios

- Inquiry now

- Related products

The characteristic of this production line is that the pouring process of polyurethane foam is continuous. The inner pipe is continuously conveyed into the pouring area together with the polyurethane foam mixture, then coated and formed with a film, and then passed through a round die head to be coated with the outer protective layer extruded by the extruder.

HQ Add:A 1210, Art & Technology Space, NO.63 Haier Road Qingdao, China. Zip Code: 266061

Tel: 86-532-80999080 80999083 Fax: 86-532-80999081 Email:hsda@qdhsd.com

![]()

Qingdao Huashida Machinery Co.Ltd. www.hsdanticorrosion.com

Qingdao Huashida Machinery Co.Ltd. www.hsdanticorrosion.com

Finished product

The flexible pre-insulated pipes production line consists of the following components:

1) Production line for inner pressure pipe (PERT, PEX)

2) Inner pipe unwinding device

3) Pipe feeding device

4) Conveyor

5) Pipe centering device

6) Preheating and temperature control

7) Film feeding device

8) High-precision foaming machine

9) Forming machine with temperature control

6) Extruder for casing pipe and water cooling

7) Pull-off device

8) Winding machine

|  |

|  |

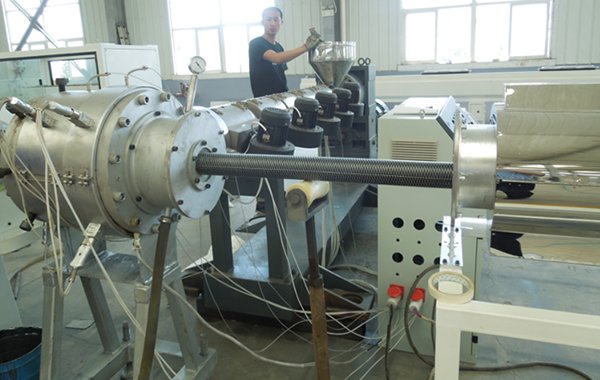

Overseas delivery

|  |

|  |

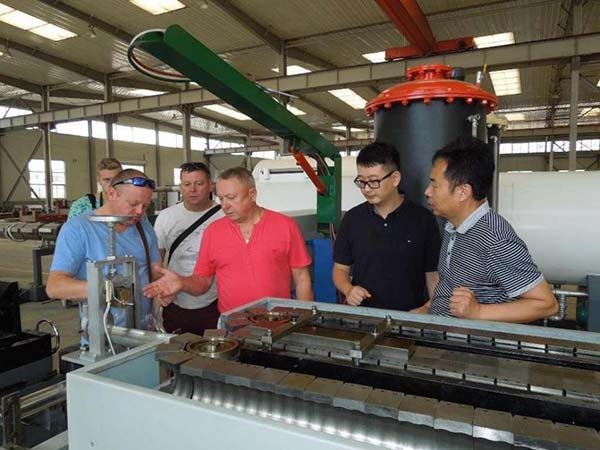

Customers visit

|  |

Overseas exhibition

|  |