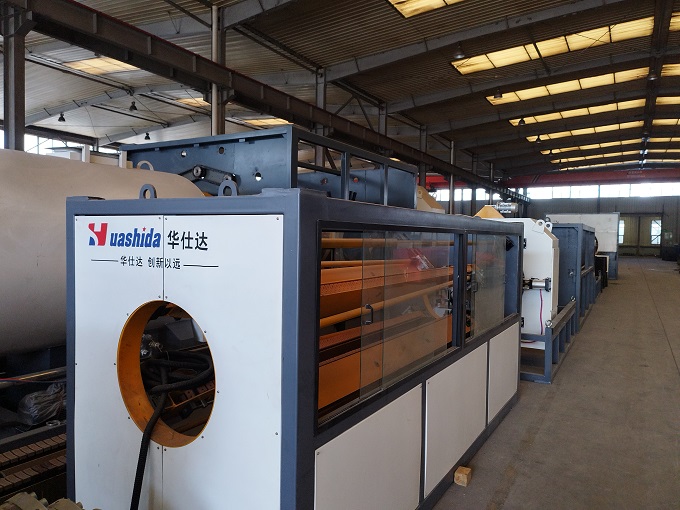

Qingdao Huashida Machinery Co., Ltd. insulation pipe production line, provide efficient, intelligent, integrated, pollution reduction, energy saving production plan for the insulation pipe manufacturing industry. The production efficiency has increased several times, achieving high-speed and efficient production, greatly improving product quality, effectively driving the downstream industrial chain of insulation pipe manufacturing, promote the rapid development of insulation pipe industry.

Huashida insulation pipe production line, through the original innovation and integrated innovation, to replace the traditional internal blowing method with closed vacuum diameter method, to replace the frame type shunt head with spiral shunt head, to replace the old clamp force tractor with friction traction machine, PLC remote intelligent control is used instead of manual operation, exhaust gas automatic collection and treatment technology is used instead of post-processing.. Many innovative points and design concepts have filled the gaps in China.

Huashida insulation pipe production line, strictly implement the enterprise standards, strictly follow the quality management system for product production and quality control. The products produced are high-end intelligent equipment and are automatic intelligent machine products.

Huashida insulation pipe production line, mainly from HDPE modified materials as raw materials, produce large diameter new composite insulation pipe. For low energy consumption, large caliber, corrosion resistance, light weight, convenient construction, long service life, high efficiency and energy saving, can be widely used in central heating, crude oil and natural gas transmission, etc.