In the field of pipeline engineering, the repair is the key link to ensure the safe operation of the pipeline, and the heat shrinkable sleeve is an indispensable material in the repair operation.

The heat shrinkable sleeve has excellent performance. It has good sealing performance, can effectively block the intrusion of moisture, oxygen and corrosive media, and prevent corrosion at the pipe patch. Its mechanical strength is high, can withstand a certain external impact and tensile, adapt to complex construction environment and pipeline operating conditions.

In terms of construction, the heat shrink sleeve is easy to operate. Simply put it on the pipe patch, and make it shrink and fit tightly on the pipe surface by heating, the repair operation can be completed, which greatly improves the construction efficiency.

The application range of heat shrink sleeve is wide, whether it is crude oil, natural gas pipeline, or water supply and drainage pipeline, it can play an important role. It provides a reliable guarantee for the long-term stable operation of the pipeline, is the ideal choice of pipeline repair, and has irreplaceable value in ensuring the safety of the pipeline and extending the service life of the pipeline.

The Production Process and Technology

1. Substrate preparation: polyethylene material with good performance is usually selected, and polyethylene sheet with certain thickness and width is made by extrusion process

2. Gluing: Evenly coat one side of the polyethylene sheet with a hot melt adhesive layer. Hot melt adhesive needs to have good bonding properties and temperature resistance to ensure that it is firmly combined with the pipe surface.

3. Forming: The coated polyethylene sheet is formed and processed into a suitable size and shape, such as a ring, according to the specifications of the heat shrink sleeve.

4. Irradiation cross linking: electron beam or gamma rays are used to irradiation the thermal shrink sleeve after forming, so that the polyethylene molecular chain cross-linked reaction occurs, improving the heat resistance, mechanical properties and shrinkage properties of the material.

5. Expansion and shaping: under heating conditions, the cross-linked heat shrinkable sleeve is expanded to reach the specified size, and it is quickly cooled and shaped to give it a "memory" effect, so that it can shrink back to the original shape and fit the pipe tightly during construction heating.

6. Inspection of packaging: Quality inspection of the produced heat shrinkable sleeve, including appearance, size, performance and other aspects of the test, after passing the packaging into the warehouse.

When using the heat shrinkable sleeve for pipeline anti-corrosion patching, the following aspects should be paid attention to to ensure the quality of the patching and the long-term anti-corrosion effect of the pipeline:

1. Construction environment: The temperature of the construction of the heat shrinkable sleeve should meet the requirements of the product specification, and it is generally not suitable for construction under an environment below 5 ° C or above 40 ° C. If the temperature is too low, appropriate preheating measures can be taken. At the same time, the relative humidity of the air should not be greater than 85%, and should avoid operating in bad weather conditions such as wind, sand, rain, snow, etc., to prevent water vapor, sand and dust from affecting the quality of the repair.

2. Pipeline surface treatment: Before patching, the surface of the pipeline patching must be strictly treated to remove impurities such as oil, rust, welding slag, etc., so that it can meet the specified cleanliness and roughness requirements. Usually, the method of sand blasting is used to expose the metallic luster on the surface of the pipeline to ensure a good bond between the heat shrinkable sleeve and the surface of the pipeline.

3. Quality inspection of the heat shrink sleeve: The appearance quality of the heat shrink sleeve should be carefully checked before use to ensure that there is no damage, deformation, deterioration and other defects, and the hot melt adhesive layer should be uniform and no leakage coating. At the same time, check whether the specification size of the heat shrink sleeve matches the pipe.

4. Heating operation: When heating, a special flame heater should be used to evenly heat the heat shrinkable sleeve so that it gradually shrinks from one end to the other to avoid local overheating or insufficient heating. During the heating process, pay attention to the contraction of the heat shrinkable sleeve and the overflow of the hot melt adhesive, to ensure that the heat shrinkable sleeve is closely fitted to the surface of the pipeline, and the hot melt adhesive is fully spilled to form a good seal.

5. Fixed and lap: After the contraction of the heat shrink sleeve is completed, it should be rolled immediately with a press roller and other tools to discharge the air, so that the heat shrinkable sleeve and the pipe surface are better bonded. The lap width between the heat shrinkable sleeve should meet the design requirements, generally not less than 100mm, the lap should be fully heated to ensure that the bond is firm.

6. Post-construction inspection: After the construction is completed, the quality of the patch should be inspected, including appearance inspection, adhesion inspection and electric spark leak detection. Appearance inspection should be free of wrinkles, bubbles, scorch and other defects; The adhesion inspection shall meet the relevant standards; Spark leakage detection should have no leakage point to ensure the corrosion resistance of the patch.

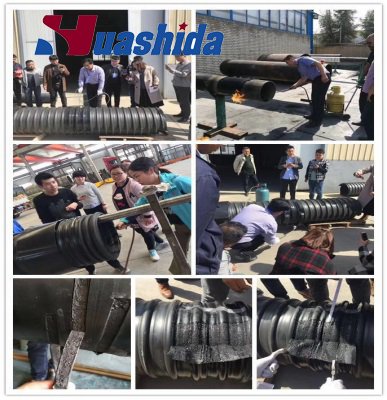

7.Heat shrinkable sleeve products video explanation:

Huashida heat shrinkable sleeves have the advantages of withstanding external impact, chemical stability and withstanding acid & alkali erosion etc.They can shrink evenly after heating, tightly cover the pipeline, simple construction and installation.The quality standards are higher than industry standards. At the same time, the product is exported to Europe, Central Asia, the Middle East, Africa, Asia, and other countries and regions, is China's famous brand manufacturer of heat shrinkabke sleeve.